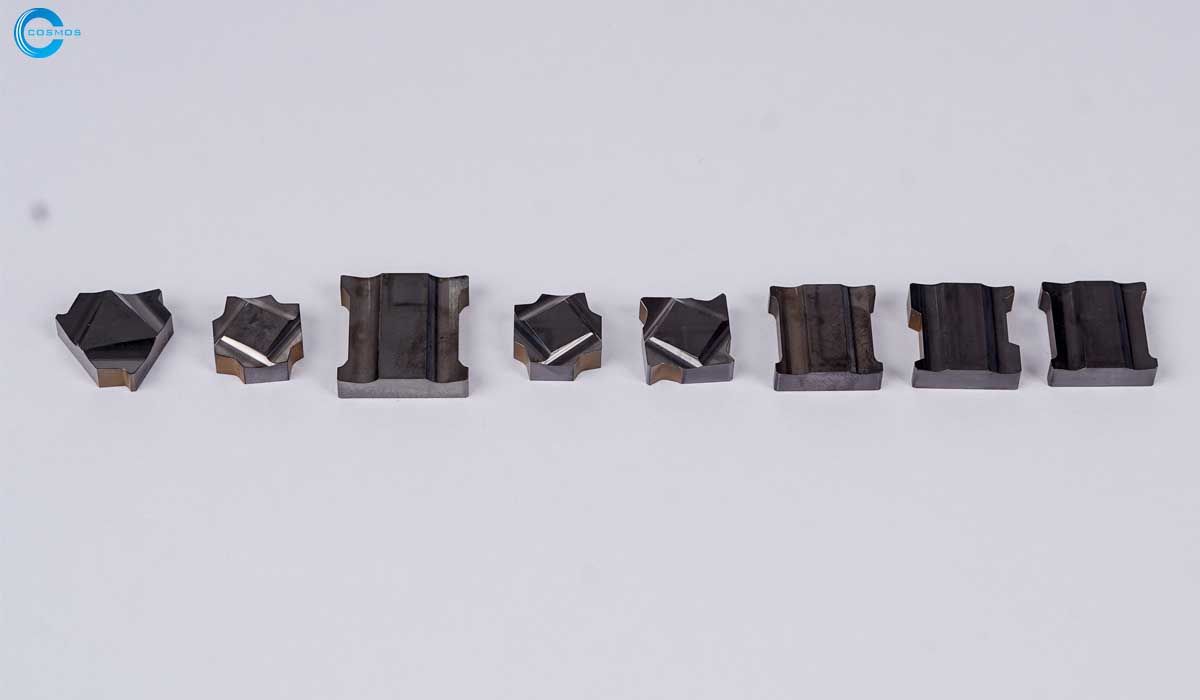

Cermet Inserts for Bearing Industry

CERMET INSERTS FOR BEARING INDUSTRY

Product Details

Cermet inserts are mainly used for formed turning process of bearing rings. Cermet Inserts are mainly used for Seal Groove, Raceway (Track) and Radius etc.... operations. Our bearing inserts are currently applied in the automatic production line (SPM) of bearing industry. Systematic solutions are available for Various types of Deep Groove Ball Bearing (DGBB), Tapered Roller Bearing (TRB), Multi-roller Bearing (MRB), Wheel Hub Bearing (WHB), other non-standard turning and CNC turning .

High quality surface on the work piece for finishing and semi-finishing. Turning/milling instead of grinding can be realized.

High Oxidation resistance-High red hardness and high cutting speed in dry cutting High chemical stability-No built-up edge

Low density-Low cost, lightweight operation, low cutting force-low noise machining. Natural resources advantage- less W&Co needed, in the long run, raw materials are easier to obtain.

Product DetailCosmos always provides our customers cermet products with good quality, competitive price, fast delivery time and reliable after services.

Cermet grades are used in smearing applications where built-up edge is a problem. Their self-sharpening wear pattern keeps cutting forces low even after long periods in cut. In finishing operations, this enables a long tool life and close tolerances, and results in shiny surfaces.

The cermet may crack after electrical discharge machining (EDM).

Both dry cutting and sufficient cooling wet cutting are feasible. Avoid insufficient cooling and thermal shock in cutting.

In the bearing, bearing races manufacturing industries adopts the forming tool for the groove, seal groove, chamfering, radius, Raceway (Track), The hardness of the work piece material and the cutting speed have a great influence on the tool life, combining with the tool material.

Features- High Temperature Resistance/Great High Temperature Performance

- Excellent surface quality in continuous finishing machining

- High red hardness and high cutting speed in dry cutting( environmental friendly)

- Long tool life for finishing applications

- Quality Assurance.(Every piece of insert is inspected.)